work in process inventory balance formula

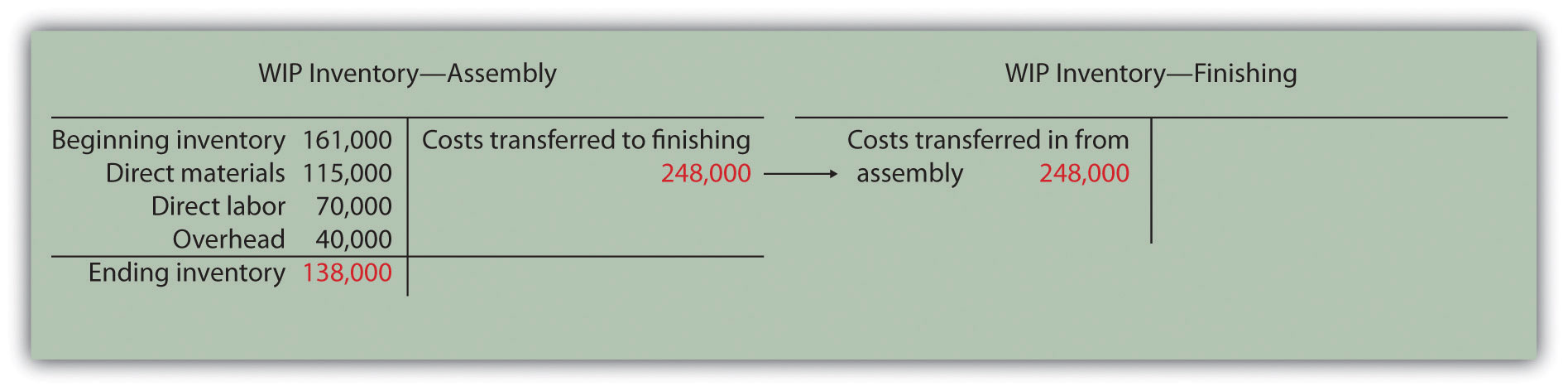

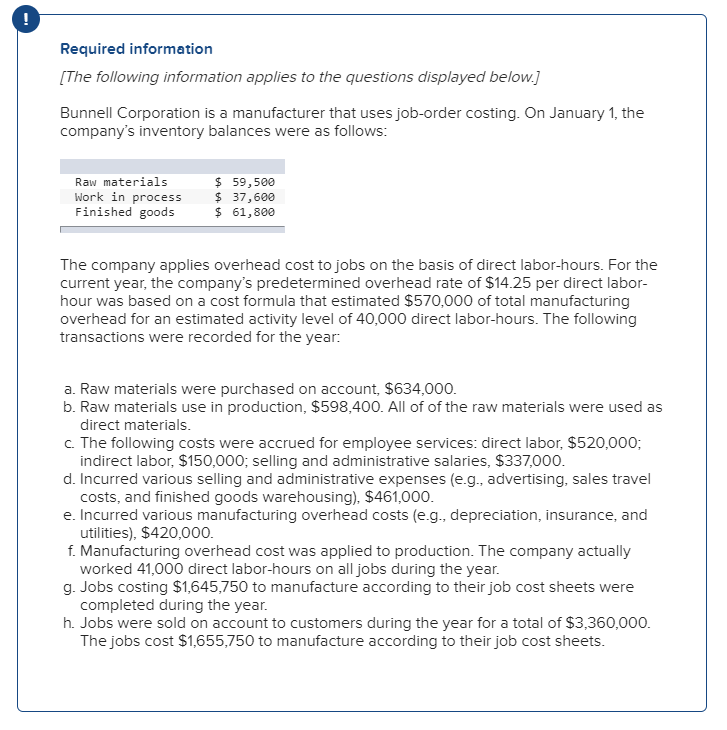

Work-in-process is accounted for by using an inventory account that includes the current cost of all inputs into the partially manufactured good. WORK IN PROCESS INITIAL WORK IN PROCESS DIRECT LABOR OVERHEAD - COST OF FINISHED GOODS.

Work In Process Inventory Wip Definition Formula Examples Product Fulfillment Solutions

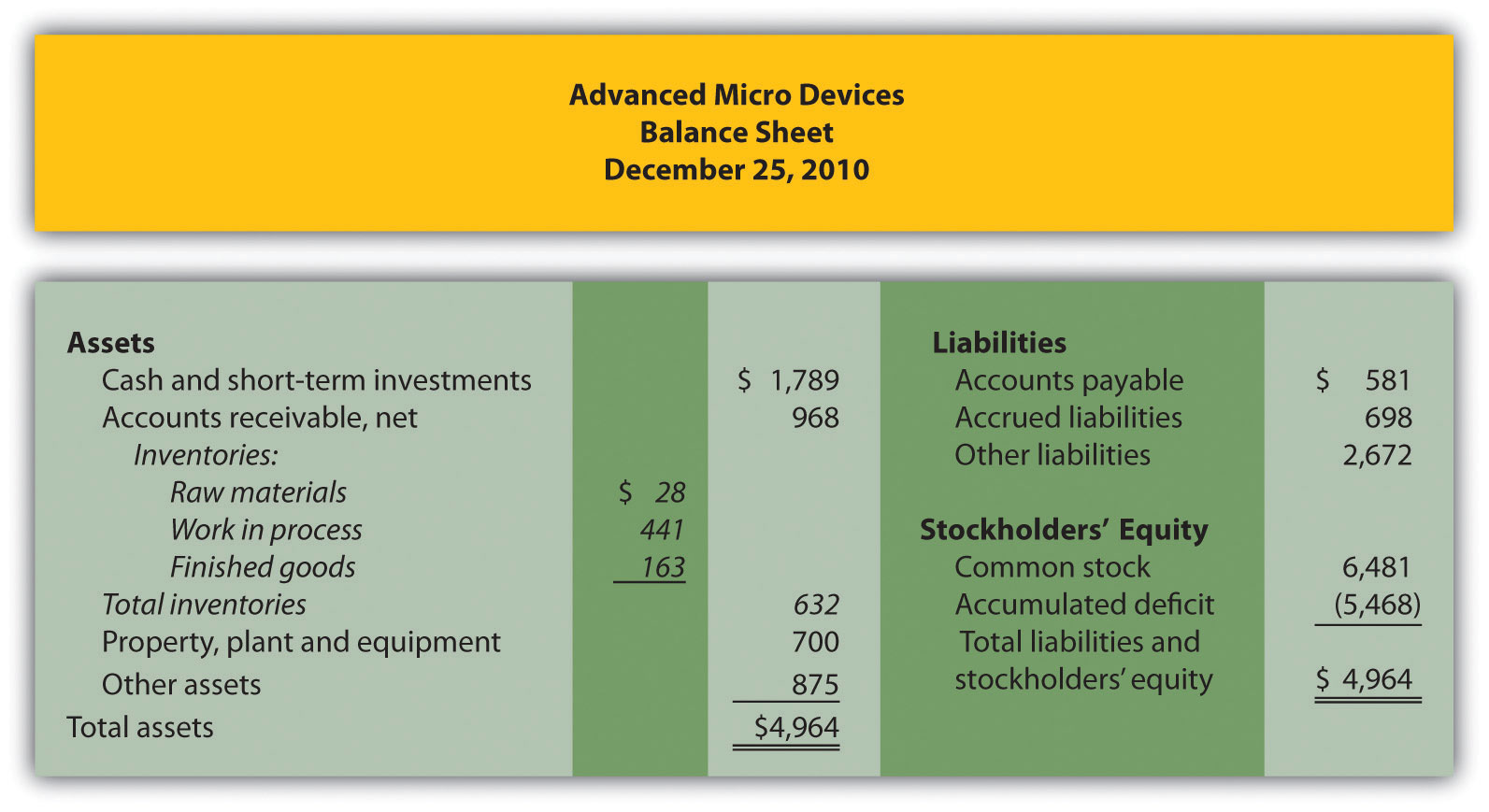

The beginning work in progress inventory is the ending WIP balance from the.

. Work in process inventory 60000. Take a look at how it looks in the formula. The difference between the sum of the beginning work in process and the costs of manufacturing is the ending work in process.

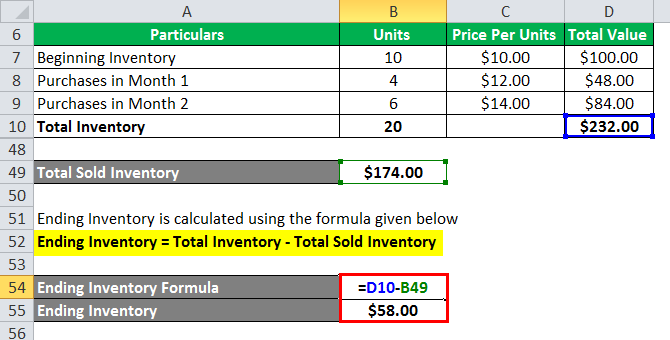

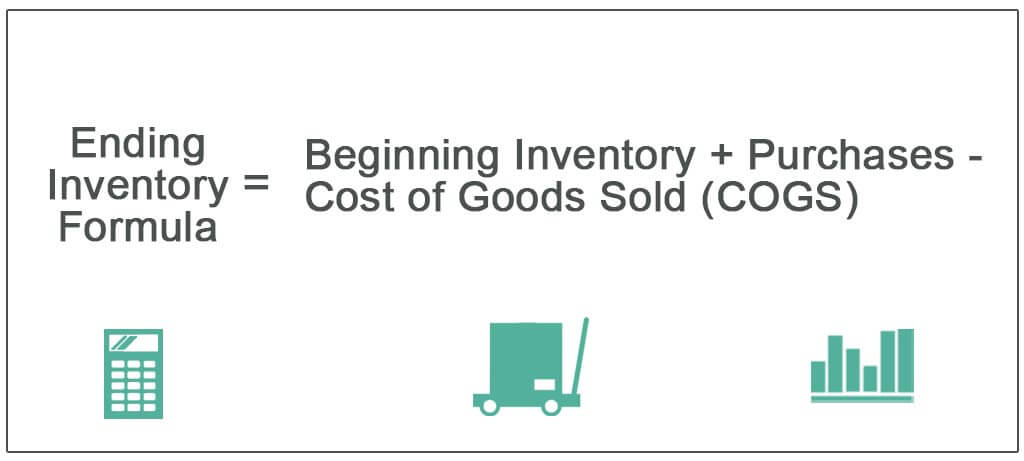

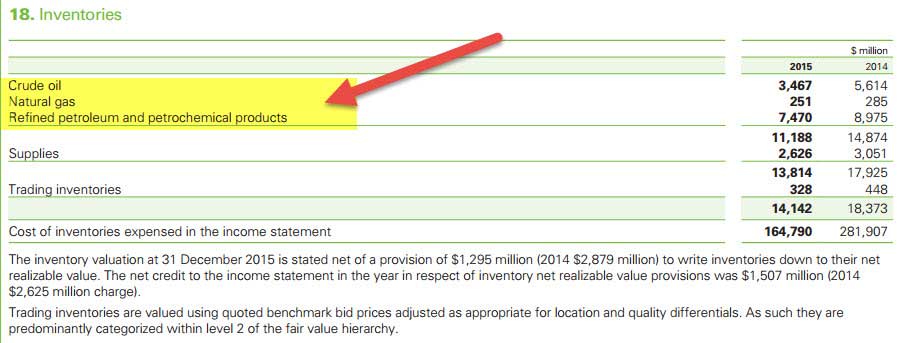

Work in process WIP inventory is a term used in production and supply chain management to refer to any materials or components that are waiting to be. Work In-process Inventory Example. The ending balance of inventory for a period depends on the volume of sales a company makes in each period.

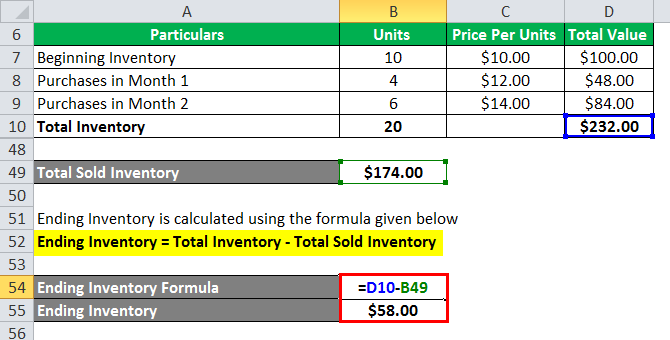

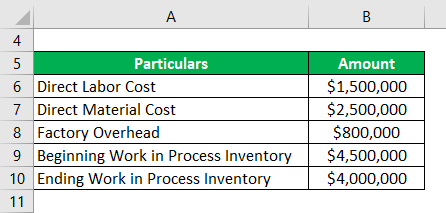

Ending Work in Progress Beginning WIP Manufacturing Costs Cost of Goods Manufactured. Also known as COGM the cost of manufactured goods is the total costs incurred in the making of a final product. Formulas to Calculate Work in Process.

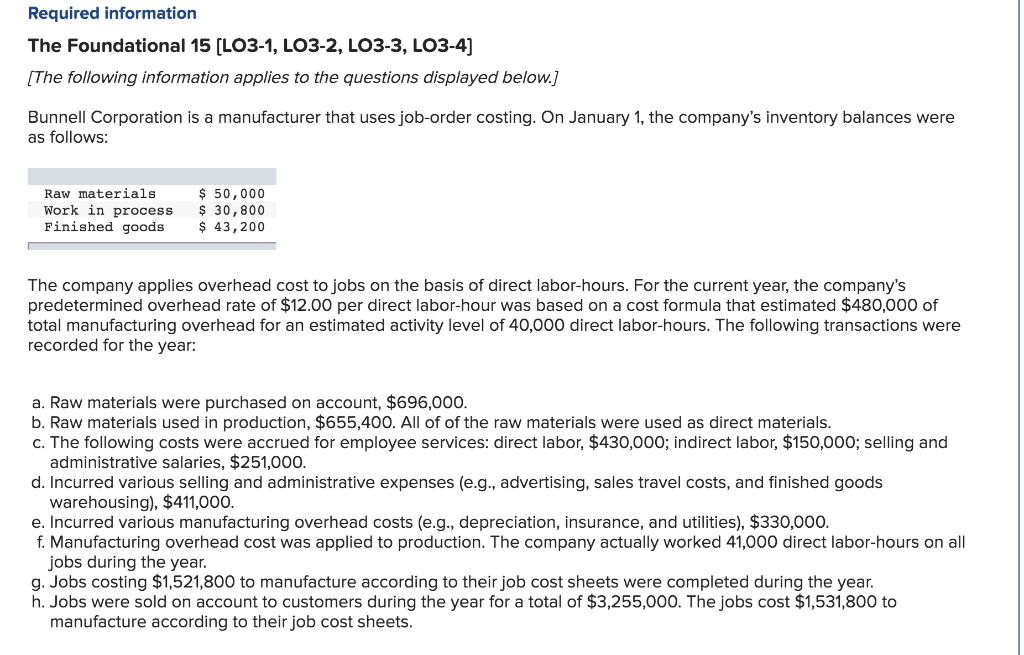

Work-in-process is inventory that has entered the production process but has not been completed at the balance sheet date. Some inventory might have one stage of machining done and other inventory might have all. With Work-in-Process software materials are tracked online in real time allowing immediate visibility into a work order and immediate responsiveness if action is needed.

Your WIP inventory formula would look like this. It is essential to differentiate between units completed out of opening WIP and units completely. 10000 300000 250000 60000.

Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs- Ending WIP Inventory. You have to know the final COGM to calculate the current WIP. Assume Company A manufactures.

Determining the balance of Inventory. In the absence of the same cost to date for each cost element cannot be calculated. Ending WIP inventory beginning WIP inventory manufacturing costs COGM.

To calculate the WIP inventory ie work in process inventory you need to use the following. The work-in-process inventory account is a. The formula for calculating WIP inventory is.

The WIP figure indicates your company has. We have worked with thousands of students from. The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity.

An important note to consider is that work in process inventory can vary greatly. The formula for this is as. In this formula COGM cost of goods manufactured.

You might have always been thinking about how to find work in process inventory.

What Is Work In Process Inventory And How To Calculate Wip

/GettyImages-975254-001-ff11e53a793446bca6e2cc49a67b29df.jpg)

Work In Progress Wip Definition With Examples

Solved 1 What Is The Ending Balance In Work In Process 2 Chegg Com

Work In Progress Wip What Is It

How Product Costs Flow Through Accounts

How To Calculate Ending Inventory The Complete Guide Unleashed Software

Work In Progress Wip Definition Example Finance Strategists

Accounting Treatment Of Work In Progress Explanation Examples Finance Strategists

What Is Inventory From Raw Materials To Finished Goods

How To Calculate Ending Inventory Formula And Steps Indeed Com

Solved Determine The Ending Balances In The Work In Process Chegg Com

Solved 7 What Is The Ending Balance In Work In Process 9 Chegg Com

Ending Inventory Formula Step By Step Calculation Examples

Ending Work In Process Double Entry Bookkeeping

3 Types Of Inventory Raw Material Wip Finished Goods

How To Calculate The Ending Work In Process Inventory

Inventory Formula Inventory Calculator Excel Template

Cost Of Goods Manufactured Formula Examples With Excel Template